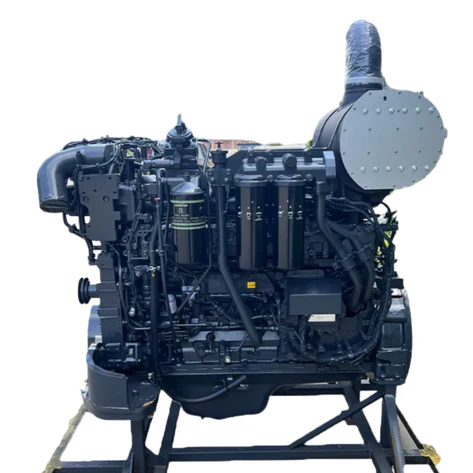

The Komatsu SAA6D140E-5 diesel engine is a high-performance, water-cooled, 4-cycle engine designed and manufactured by Komatsu for integration into large-scale machinery such as bulldozers, excavators, and off-highway trucks. This engine model belongs to Komatsu’s ecot3 series, emphasizing ecology, economy, and high output while meeting stringent emissions standards.

Key specifications include:

- Engine Type: 4-cycle, water-cooled, direct injection.

- Number of Cylinders: 6 (inline configuration).

- Bore x Stroke: 140 mm x 165 mm (5.51″ x 6.50″).

- Displacement: 15.24 liters (930 in³).

- Aspiration: Turbocharged with air-to-air aftercooling and cooled EGR (Exhaust Gas Recirculation) for enhanced efficiency and reduced emissions.

- Fuel System: Direct injection with electronic governor for precise control.

- Lubrication: Gear pump with full-flow filter; engine oil capacity approximately 52 liters (13.7 U.S. gal).

- Cooling: Water-cooled with hydraulic fan drive; coolant capacity around 100 liters (26.4 U.S. gal).

- Dry Weight: Approximately 1,400–1,500 kg.

Power output varies by application but typically ranges from 306 kW (410 HP) net with hydraulic fan to 386 kW (518 HP) gross at 2000 rpm, with maximum torque up to 2,167 Nm (1,600 lb.ft). For example, in the D275AX-5 bulldozer, it provides 335 kW (449 HP) net at 2000 rpm, while in the HD405-7R truck, it achieves 371 kW (498 HP) net.

Fuel efficiency is optimized through technologies like the Common Rail Injection (CRI) system, automatic torque converter lockup, and mode selection (Power and Economy modes) that adjust horsepower based on load conditions. This results in lower fuel consumption during operations, with features such as auto downshift and hydraulically controlled cooling fans further reducing operational costs.

Emissions compliance meets EPA Tier 3, EU Stage 3A, and equivalent standards (including EPA Tier 2 and EU Stage 2 in some variants), incorporating a cooled EGR system to minimize environmental impact without sacrificing power.

Additional features enhance reliability and operator comfort, including rubber-mounted installation to reduce noise and vibration, an Automatic Idling Setting System (AISS) for quick warm-ups, and extended maintenance intervals (e.g., 500 hours for oil changes). This engine is ideal for demanding tasks in mining, construction, and earthmoving, ensuring high productivity, durability, and seamless integration with Komatsu’s powertrain systems.

All information is derived from official Komatsu technical brochures and specifications for accuracy and trustworthiness.

Reviews

There are no reviews yet.